January 4, 2016 – impact analysis for line production processes, with and explain how to shorten changeover time to improve earnings

If you want to improve plant output, adapt to changing market demand or accelerate the speed, then you should seriously look into how to shorten changeover time or re If every time you or a production line in a machine, consume an average of one hour to change line, average weekly 8 to 10 times to re-set; then, a week is wasted one working day of production , annual waste 52 working days of production! Thus, the high cost of the workshop changeover process, serious erosion of your potential profits! Now, we’ll let you: ” Rethinking changeovers thing ” .

In the production process, change the line refers to the same machine or on the same production line, the production of a certain product, converted to the production of another product. In other words, changing the meaning of the line, that is, from the end of production of a product, to begin production of intermediate goods required next time. In the concept of lean manufacturing, the ability to quickly change the line is crucial because it determines whether a production line quickly and flexibly adapt to actual production requirements of many varieties. In addition, rapid changeover also avoid hoarding goods, exempt increase in production costs, and ultimately wasteful.

Changeover time can be as short as a few minutes to several hours long, will be carried out several times a day (depending on production requirements). Overall, the changeover process can be divided into three parts, demolition, settings, and trial production.

Removal is from the production line, the complete removal of a product, materials and components required, adjustments can be involved in a range from a simple adjustment, mainly to adjust to completely disassemble the entire production line again.

Setting refers to the whole process of adjusting the device, including actions to adjust production equipment with the next production, or replacement can not fit ” components ” to conform to the manufacture of new products. In general, the settings need to be adjusted and replace these two steps.

Trial production means before the official start of production in a product, you need to spend much time in the review of the entire production testing process. The so 100% pass-through rate.

Thus, the changeover is a time SMT production efficiency and low line of the main reasons for loss of profits. If thou want to calculate the cost of changing the line, you have to determine the profit target for each production line, and thus an extension of the computational cost.

Each SMT line profit target

| Per year | per month | per hour | every minute | Per second | |||||

| $ | 10,000,000 | $ | 833,333 | $ | 5,000 | $ | 83 | $ | 1 |

| $ | 15,000,000 | $ | 1,250,000 | $ | 7,500 | $ | 125 | $ | 2 |

| $ | 25,000,000 | $ | 2,083,333 | $ | 12,500 | $ | 208 | $ | 3 |

| $ | 50,000,000 | $ | 4,166,667 | $ | 25,000 | $ | 417 | $ | 7 |

In minutes of the profit target

| 10 minutes | 20 minutes | 30 minutes | 40 minutes | 50 minutes | 60 minutes | |||||||

| $ 10M | $ | 833 | $ | 1,667 | $ | 2,500 | $ | 3,333 | $ | 4,167 | $ | 5,000 |

| $ 15M | $ | 1,250 | $ | 2,500 | $ | 3,750 | $ | 5,000 | $ | 6,250 | $ | 7,500 |

| $ 25M | $ | 2,083 | $ | 4,167 | $ | 6,250 | $ | 8,333 | $ | 10,417 | $ | 12,500 |

| $ 50M | $ | 4,167 | $ | 8,333 | $ | 12,500 | $ | 16,667 | $ | 20,833 | $ | 25,000 |

These two charts are split by time profit target each production line, which can be found in two cases:

- A waste of time it is impossible to make it up

- Save time is to increase profitability

You might ask, in the end how you can save changeover time, so as to enhance profits? First, let’s think about this question: How you should calculate the changeover time? Where we should begin a process, where a process end?

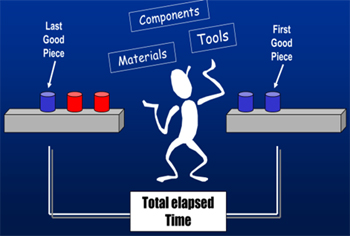

In terms of a single unit machine to calculate the starting product changeover time is the last piece of circuit board from the end of the batch to the next batch of the product until the first piece of circuit board into the machine. In terms of a production line to calculate, for the line is the beginning of a number of products from the last piece of circuit board assembly line from the last one machine to the next batch of products to enter the first piece of circuit board production line until the first machine. In calculating the changeover time, we can not be calculated only downtime but also included the production of the first product to complete, that trial production.

In fact, there are different ways to calculate the changeover time. However, the changeover is just one of the factors affecting the efficient production patterns . To fully understand how to achieve efficient production, we must first recognize that overall equipment efficiency ( OEE) , and it will consider various factors overall, including down time ( production time ) , performance and device yield.

If you want to know more? Please pay close attention to our blog article will teach you how to calculate OEE.